The assignment was to design a kitchen tool. I decided to make a spatula. Exciting I know. Here are some sketches.

I had a hard time choosing one I wanted to make. Mostly because spatulas are boring. But, do you know what's not boring? Thats right, sex toys. Why not make a spatula that is also a sex toy?

...extra fun in the kitchen. The most difficult part was machining the handle/toy. It is made of solid aluminum and hand turned on the lathe.

The blade was cut on the plasma cam and then I polished everything to nice finish.

I haven't tried it out yet but I'm sure it does just fine flipping burgers.

The Design Process

My name is Josh Shaffer and I'm blogging about being an Industrial Design a Mechanical Engineering student in Denver, Colorado. Posting about what I am doing as a design student an engineering student, what inspires me and the design I like.

Thursday, February 14, 2013

Monday, December 13, 2010

A Good Article For Any Design Student To Read.

Design students read this. I found this a very informative read. It is an article about the state of design education in America right now. Coming from an education in Fine Art I understand where the author is coming from. I have a BFA in painting & drawing and one in sculpture & drawing. The Bachelor of Fine Arts I have had no distinct career to direct the students into. It's Art. A career in art has a need for talent, entrepreneurial savvy, business, networking skill, and knowing how to market yourself really well. The only thing taught in Art School is how to paint, how to draw, and how to sculpt things (with a few exceptions). Thus the courses were based on the "how to" curriculum. Only a couple courses were about the business of being a professional artist. No where near what is really needed to actually make a living as an artist. I see a little of this the design program that I'm currently enrolled in.

As soon as I read this piece a bell started ringing in my head. I have seen (even applied to) schools that accept ANY majors into a MA of Industrial Design with a portfolio and a BA. These programs fill up fast. And of coarse they do. I'm sure that these schools want to produce excellent designers but what's most important to them is making money (they have to balance their budget just like everyone else).

I have just started a new school as an Industrial Design student. With my past experience I have a since of what I'm getting myself into. I see the pros and cons of the program i'm in. The pros are important but I think it is the cons in the program that I need to focus on in order to compensate for myself and make it as a designer. I am old enough to have some real world experience and therefore know that the school part of this is easy (this is something I didn't know this the fist time around) it's making a living at what I love that is going to be the hard part.

All in all I think that I will get as much as I put into the design program I'm in. I see a lot of the students that are in the mindset of entitlement. I get it, I was them once. They're young, I was young and had no idea of what kind of challenges life has to offer. Yeah, it took me awhile but I know what I want now and i'm going to work hard for it and I think my schooling is going to be an integral part of me making it.

So after reading the article and my bog post try and hop on over to the Core 77 forum and see what everyone else has to say.

As soon as I read this piece a bell started ringing in my head. I have seen (even applied to) schools that accept ANY majors into a MA of Industrial Design with a portfolio and a BA. These programs fill up fast. And of coarse they do. I'm sure that these schools want to produce excellent designers but what's most important to them is making money (they have to balance their budget just like everyone else).

I have just started a new school as an Industrial Design student. With my past experience I have a since of what I'm getting myself into. I see the pros and cons of the program i'm in. The pros are important but I think it is the cons in the program that I need to focus on in order to compensate for myself and make it as a designer. I am old enough to have some real world experience and therefore know that the school part of this is easy (this is something I didn't know this the fist time around) it's making a living at what I love that is going to be the hard part.

All in all I think that I will get as much as I put into the design program I'm in. I see a lot of the students that are in the mindset of entitlement. I get it, I was them once. They're young, I was young and had no idea of what kind of challenges life has to offer. Yeah, it took me awhile but I know what I want now and i'm going to work hard for it and I think my schooling is going to be an integral part of me making it.

So after reading the article and my bog post try and hop on over to the Core 77 forum and see what everyone else has to say.

Sunday, December 5, 2010

The Problem: episode 1, part 15 (Figuring Out The Desk Top- AKA: Model Making)

Before I get started on the joys of the models I wanted to show how the White Oak looks after I had put some oil on it. On the right is the fumed oak and the left is what the whole thing is going to look like after one coat of linseed oil. It turned out a lot darker than I expected. At first I was worried that I wouldn't like it but it has started to grow on me. The color is unexpectedly rich which is nice. Give me a few more weeks and I'm sure I'll think it's the best thing since sliced bread.

As for this model I am going to try and see what a square top (first was all curvy and stuff) with an cabinet type thing on top of that opens but still fits all of my technology inside when it closes. I'm asking miracles with this one I know. Just laying this thing out has taken me forever. My first try started out nice but after I figured out it would take up an entire wall (the big one) in our living room I gave it another shot. And about halve a dozen shots later this is what I have came up with. It all started with that awesome desk I saw at the vintage furniture store.

Started with the desk top. Making it big enough to fit a couple of drawers and cable storage and some other nooks and crannies for putting odds and ends.

Here is the top piece. Making it open to no bigger than the desk top was still the hard part.

The goal is to fit everything inside. . . of this closed box.

But make use of the entire desk top when it's open.

My solution is to have the monitor on an extendable arm and my laptop on a tray that can slide back and forth under the monitor.

Then I added some shelves for the printer and other things.

Monday, November 29, 2010

The Problem: episode 1, part 14 (The Fumed Finished)

After stuffing myself silly over the Thanksgiving holiday I managed to get back to work.

Working on the final touches with putting the leg and rail together. Here is the wedge that holds everything together.

Working on the final touches with putting the leg and rail together. Here is the wedge that holds everything together.

It turned out more sturdy than I had hoped. The thing is as sturdy as a rock. If I wasn't using it as a computer desk I could easily use it as a workbench.

I went old school with the finish on this one. Fuming the white oak with ammonia. This technique gives the oak a nice deep burnt umber color.

To do this I had to build an air tight box to fit all of the pieces of my leg and rail in. I made this one out of cheap 1"x 2"s and 2mil plastic.

All of the pieces are held apart by screwing them into some scrap wood. Then I poured the ammonia into a bowl.

And then covered the top and taped down all of the edges in order to make it as air tight as possible.

Then I waited about 24 hours.

It's hard to tell how much the color of the wood changed in this lighting. It's my porch light because I took all of these pics at night. Since it's winter time here in Colorado that means I took the pics after 5:00PM.

Before the fuming the aluminum rod was not that noticeable. So you can see the wood has darkened quite a bit. The color will pop as soon as I put some oil on it. I can't wait but if I bring it in the apartment right now I will have the whole place smelling of ammonia and that's not good. I have to keep the wife and dog happy so I will wait until tomorrow.

Sunday, November 21, 2010

The Problem: episode 1, part 13 (The Big Glue Up)

Really busy week this week. I got a lot done, just not a lot done with this leg and rail assembly. What I did do was a major step in getting the thing done. I have got it ready for the finish.

Had to cut a pile of shims for the tenons and lay out where they go.

Had to cut a pile of shims for the tenons and lay out where they go.

These are the blind (go into a hole that has a bottom) tenons that I am putting the shims in. As the shims bottom out in the mortise they are forced back up into the tenon making everything nice and tight.

First is the glue.

Lining it up.

And applying the force.

More force.

And a little more force. I would like to take a second to thank Mr Greg Burns for taking these action shots of me. Good Job, thank you.

The upper tenons are through tenons so I could put the shims in after I fit the two pieces together.

And here they are almost ready to be finished.

Monday, November 15, 2010

Sunday, November 14, 2010

The Problem: episode 1, part 12 (The Last Mortise And Securing The Tenons)

I enjoy doing things by hand sometimes. Working with good old hand tools keeps my hands honest.

To strengthen the rail tenon I drilled a 1/4" hole just past the mortise I just made.

Then I cut some 1/4" round aluminium just a little larger than the height of the tenon.

And pounded it through the tenon with a hammer.

All I have to do now is file the aluminium flush and do some finish sanding to get things ready for the finish.

Saturday, November 13, 2010

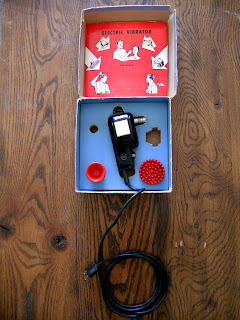

Hands Down Best Thrift Store Find Ever!

That's right is't a vintage vibrator. This is like most of my interests all rolled up into one little package. I got old school graphic design, product design, "sex toy" design (massager yeah right) and I found it at the thrift store for less than $5.00.

Subscribe to:

Posts (Atom)